- Home

- About Us

Zinc/Aluminium Die Casting Company

- Established in 1983

- Plant Size: spanning over 3,960 square meters

- Quality Certification: ISO 9001:2015 certified

- Environmental Compliance: Adhering to ROHS, REACH, and Conflict-Free Mineral Policies, actively pursuing ESG-related certifications.

Chi Tai Casting Industrial Co. Ltd. specializes in manufacturing aluminum and zinc alloy die castings. Renowned for our pioneering industrial innovations, we offer customized precision solutions tailored to the unique needs of our clients.

Our team of expert engineers collaborates closely with clients to transform design requirements into feasible and efficient die cast solutions. We serve a diverse range of industries worldwide, including automotive, bicycle, lighting, natural gas, electronics, and office appliances and communications equipment.

Chi-Tai has established a sterling reputation for reliability and quality, earning the ISO-9001 certification in 2002, and actively pursuing ESG-related certifications. Our commitment to industry leadership is reflected in our rigorous management and technical excellence.

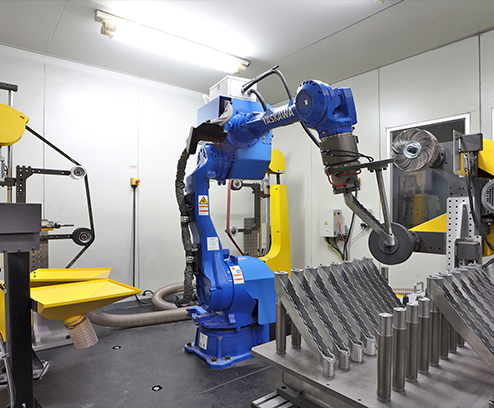

In 2019, Chi-Tai embraced grinding automation by incorporating Yaskawa robotic arms, significantly boosting production efficiency. Our integration of Industrial Internet of Things (IIoT) technologies showcases our dedication to sustainable, innovative practices, positioning Chi-Tai at the forefront of die-casting innovation.

Chi-Tai offers professional customized manufacturing services with a one-stop integrated manufacturing approach. This strategy ensures rapid delivery, reduces inventory for clients, and maintains strict quality control.

Chi-Tai has a professional engineering team that has expertise in the latest forms of technology and 3D drafting software, including Pro-E CREO & SolidWorks. We collaborate closely with you to ensure your product design meets your requirements after manufacturing.

We use central melting furnaces for material processing, allowing for temperature control and impurity filtration. The die-casting produces uniformly dense products that are less prone to breakage, design flaws, and feature stable weight and smooth surfaces. Manufactured using a semi-automatic cyclic production system, this process minimizes labor and is environmentally friendly.

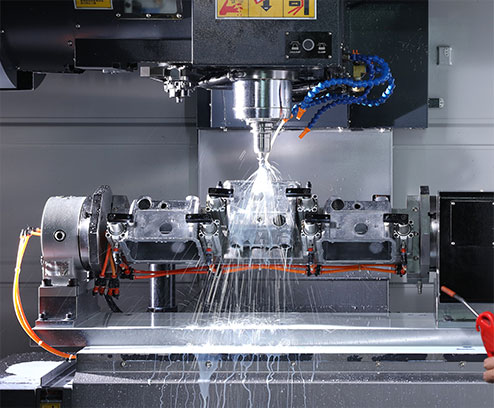

- Precision CNC Machining

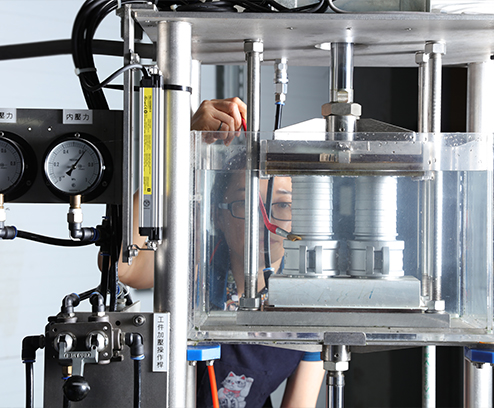

CNC machining, sandblasting, vibratory grinding, and the introduction of Japanese Yaskawa robotic arms for automated grinding. - Airtight Leak Testing

specializing in gas and raft leak testing with dedicated lines. - Surface Treatment

powder coating, liquid coating, electrophoretic deposition, anodizing, among other functions. - Custom Assembly Services

we specialize in assembling products by combining parts manufactured on-site. - Packaging and Container Transportation

direct loading of products from the factory onto containers for port shipment.

Chi-Tai is recognized by renowned domestic and international manufacturers. We welcome clients to provide design drawings and samples for joint development. We pledge to serve you with integrity and reasonable costs, striving to manufacture products that meet your utmost satisfaction.

As an ISO-certified aluminum and zinc die casting manufacturer, we pride ourselves on:

- Decades of Expertise: since our establishment in 1983, we have accumulated over forty years of experience in manufacturing die casting parts.

- Comprehensive Manufacturing Solutions: we provide a One-Stop Manufacturing Solution for OEM/ODM projects, encompassing machinery production, surface treatments, product assembly, and more.

- Precision Manufacturing: our plant is equipped with a variety of precise measuring instruments, ensuring high-quality manufacturing standards.

- Integrated R&D Team: our dedicated R&D team offers expert product recommendations, focusing on manufacturing and process design optimization.