- Home

- Quality Inspection

-

Engineering Feedback on Product Designs

-

Die-Casting Tooling Development and Maintenance

-

Die Casting

-

Deburring

-

CNC Machining

-

100% Inspection for Airtight Testing

-

Surface Treatment

-

Quality Inspection

-

Assembly Services

-

Packaging and Transportation

-

Dedicated Production Line Services

Quality Inspection

1 Equipment Utilized by Chi-Tai

Chi-Tai employs three-dimensional measuring instruments and 2.5D projectors. Our in-house team of technicians conduct our tool inspection internally, enabling us to swiftly customize and meet clients’ specifications.

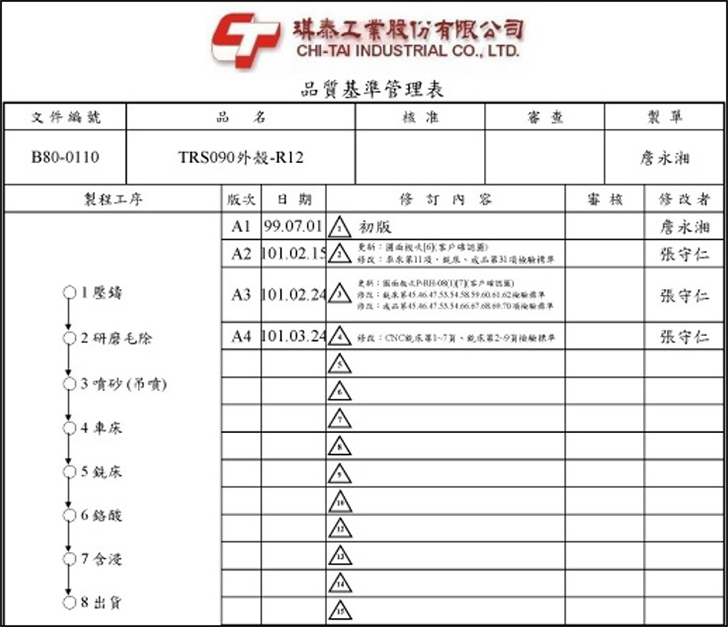

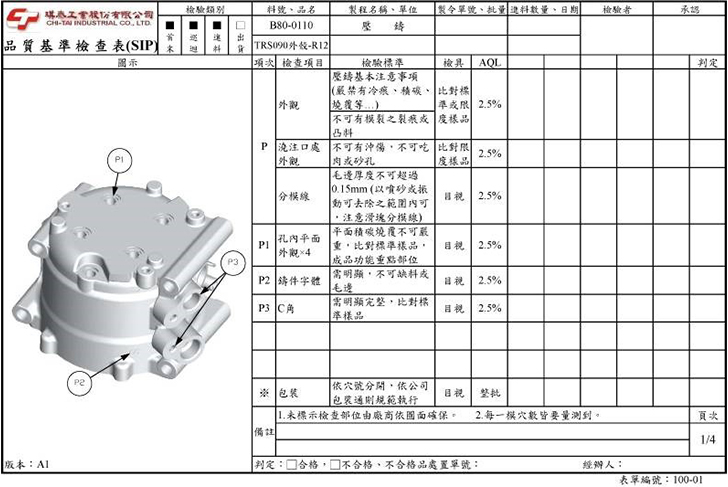

2 Chi-Tai Designs a Dedicated SIP for Each Product

Quality control has remained a continual focus within the aluminum die-casting industry. We have introduced the Standard Inspection Procedure (SIP) system on our premises to ensure the consistency of product quality control. This system enables every production line employee to conduct self-assessment based on clients' engineering blueprints, which is customized by Tailored by Chi-Tai's engineering team during product development. The SIP system plays a pivotal role in monitoring quality throughout the manufacturing process. The advantages brought about by the SIP inspection system in our factory are as follows:

Enhanced Product Quality: The SIP inspection system enables real-time monitoring of the quality status during manufacturing, facilitating immediate actions upon identifying any quality issues. This significantly elevates product quality, meeting the demands for high-quality products from our clients.

Cost Reduction: Utilizing the SIP inspection system aids in timely detection of issues during production, preventing the escalation of problems in subsequent manufacturing stages. This minimizes unnecessary losses, enhances production efficiency, and reduces production costs.

Competitive Edge: Product quality stands as a key factor determining a company's competitiveness and growth. Implementing the SIP inspection system substantially enhances our product quality, thus boosting the company's competitive edge.