Aluminum Alloy Die-Casting

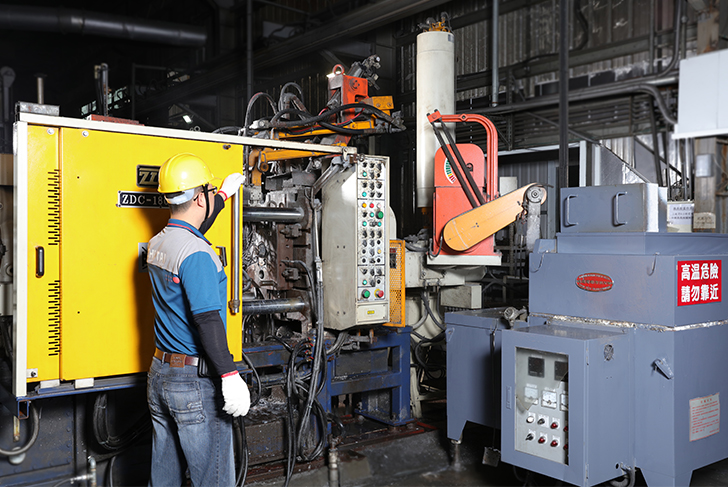

We utilize a fleet of up to 40 die casting machines with tonnages ranging from 180 to 1,200 tons, enabling the production of both small and large batches of aluminum die castings. Our capabilities extend to the manufacture of extremely small and thin parts, with a minimum weight of 2 grams, and a minimum thickness of 1.2 millimeters.

Chi-Tai offers a variety of aluminum alloy die casting materials, which include:

- ASTM Standards: A356, A360, A380, A383

- These alloys adhere to the standards set by the American Society for Testing and Materials (ASTM), which are widely recognized across the United States and other countries.

- Each alloy features unique characteristics. For example, A356 is characterized by having excellent mechanical properties that are ideal for complex shapes; A380 ensures dimensional stability, making it suitable for precise applications; A383 provides high strength and dimensional stability, fulfilling demanding mechanical performance requirements.

- JIS Standards: ADC1, ADC3, ADC6, ADC10, ADC12

- These alloys comply with Japanese Industrial Standards (JIS), which are predominantly used in Japan and other Asian countries.

- Like ASTM alloys, each JIS alloy has distinct properties. For instance, ADC12 is recognized for its superior fluidity and casting performance, making it widely applicable in the manufacturing of automotive and electronics components.

Our expertise in die casting ensures precision and reliability across a wide range of industrial applications.

Advantages and Applications of Aluminum Die Casting

Aluminum die casting delivers several advantages:

- High Precision: producing intricately shaped and precisely dimensioned castings, making them ideal for demanding engineering applications.

- High Efficiency: rapid production speeds enable large-scale manufacturing with shorter lead times, helping to reduce costs.

- Lightweight: Aluminum alloys have a density of approximately 2.7 g/cm³, which is significantly lighter than zinc alloys, contributing to weight reduction, energy efficiency, and enhanced performance.

- Superior Mechanical Properties: Aluminum die castings offer strength, high-temperature resistance, and corrosion resistance, suitable for various industrial applications.

- Excellent Heat Dissipation: Thanks to their outstanding thermal conductivity, aluminum die castings are perfect for components requiring efficient heat dissipation, such as electronic heat sinks and LED lamp housings.

- Ease of Machining: Aluminum alloys are highly machinable, making them well-suited for manufacturing complex parts requiring subsequent machining and surface treatments.

- Environmental Sustainability: Aluminum is recyclable and can be reused indefinitely without degrading in quality, minimizing environmental impact and supporting sustainable development goals.

|

|

Here is a simple comparison between aluminum die casting and zinc die casting:

| Feature | Aluminum Die Casting | Zinc Die Casting |

|---|---|---|

| Precision | High, suitable for complex shapes and precise dimensions | High, stable size control, suitable for high precision needs |

| Efficiency | High, suitable for large-scale production | High, fast production speeds, suitable for high-volume demands |

| Weight | Lightweight, contributes to product light-weighting | Heavier, higher density |

| Mechanical Properties | Excellent, high strength, high temperature resistance, corrosion resistance | Lower, strength and hardness not as good as aluminum alloys |

| Thermal Conductivity | Excellent, suitable for efficient heat dissipation | Lower, not suitable for high-efficiency heat dissipation applications |

| Machinability | Good, easy to machine and surface treat | Excellent, good machinability, high surface quality |

| Environmental Friendliness | Good, recyclable with minimal environmental impact | Good, easy to recycle and reuse |

| Cost | Higher, higher raw material and processing costs | Lower, lower production costs, significant economic benefits |

| Mold Life | Moderate, limited by wear | Long, zinc alloy molds can exceed 200,000 cycles |

| Size Limitations | Yes, suitable for small to medium-sized precision components | Few, suitable for complex and precision structures |

CastingApplications of Aluminum Die Casting Technology

Aluminum die casting technology is widely used across various industries, including:

- Automotive Industry: producing components, such as engine covers, gearbox housings, and wheels.

- Aerospace: manufacturing aircraft structural components, engine parts, and other lightweight, high-strength components.

- Electronics: creating enclosures, connectors, and heat sinks with excellent thermal conductivity and electromagnetic shielding properties.

- 3C Products: developing components for computers, communication equipment, and consumer electronics that require high precision and durability.

- LED and Lighting Equipment: Producing housings and heat sinks for LED lamps to ensure efficient heat dissipation and durability.

- Home Appliances: manufacturing components for household appliances, such as power tool housings and handheld device parts.

|

|

|

Aluminum die casting technology is recognized for its lightweight properties, superior strength, and exceptional heat dissipation capabilities. Chi-Tai remains committed to continuous improvement and excellence, delivering high-quality aluminum die casting solutions tailored to various precision and performance requirements.