- Home

- Engineering Feedback on Product Designs

-

Engineering Feedback on Product Designs

-

Die-Casting Tooling Development and Maintenance

-

Die Casting

-

Deburring

-

CNC Machining

-

100% Inspection for Airtight Testing

-

Surface Treatment

-

Quality Inspection

-

Assembly Services

-

Packaging and Transportation

-

Dedicated Production Line Services

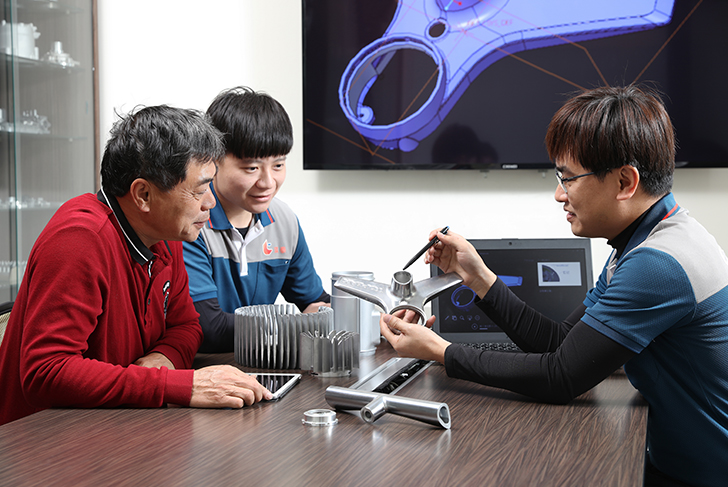

Engineering Feedback on Product Designs

Chi-Tai provides different types of OEM casting services. We have a strong engineering design team that provides mold making, as well as reviews casting designs. Our personnel can recommend improvements to ensure that molds and castings can function at their highest efficiency. In addition, we also propose measures to prevent future potential problems, bringing the highest benefits to our clients.

Our team of experienced engineers will work with you from the beginning to the end of the project to complete the following tasks:

1 Supported File Types

- Pro-E CREO

- Solidworks

- Auto CAD

Chi-Tai also supports a wide range of 2D and 3D file types.

2 Predictive Engineering Design Method:

- Conducting a thorough design review of the customer's design drawings to identify potential or existing quality issues.

- Provide castability analysis and recommendations to reinforce the efficiency of the client's design drawings while making the most efficient use of product materials.

3 Mold Structure Design and Mold Development

Chi-Tai has the technical expertise to effectively resolve molding problems, such as air hole issues, and can provide the following services:

- Mold structure design

- Mold flow analysis

- Material and fabrication condition setting

- Meeting precision requirements

4 Mass Production Process Planning

Chi-Tai provides casting, machining, surface treatment, assembly, testing processes etc. We can plan and arrange the most suitable process to address clients’ requirements.

5 Collaborative Design and Development

Chi-Tai can follow customer installation conditions, appearance requirements, and performance conditions, Our personnel can collaborate with clients on design, verification, making modifications, and reliability testing to meet the overall product design and functional requirements to create the ideal final product.

Product Development and Process Design Capability

The process design and die-casting development engineering teams are going to meet customer requirements in the early stages of product development to create cost effective products. Our engineering team has expertise with using computer-aided simulations and mold flow analysis software to significantly reduce costs, shorten development times, and improve productivity and quality.

Your Trusted Manufacturer and Finished Parts Supplier

We recognize that technological development is the key to success. Hence, we invest in maintaining our industry leading position. Different forms of technology, including mold flow software, computer imaging, six-axis robotic arms, CNC, and the latest Pro-E and CAD/CAM, are our strengths . Our sales, engineering and quality assurance teams, as well as customer management teams, actively engage in promoting customer satisfaction and value from the earliest production stages. We also continue investing in product concept development and rapid prototyping, as well as contract manufacturing capabilities, to create more value for our clients.