- Home

- Application

- High-Efficiency Aluminum Die-Cast Camlock Couplings: Reliable and Durable Connectivity

High-Efficiency Aluminum Die-Cast Camlock Couplings: Reliable and Durable Connectivity

Camlock Couplings, often referred to as Cam & Groove Couplings, are essential for the quick and efficient connection and disconnection of liquids and gas in pipeline systems, They are favored for their simple operations. Chi Tai Casting provides a versatile selection of die-cast models, including types A, B, C, D, E, F, DC, and DP, which can be configured to suit a wide array of pipeline needs.

Advantages of Aluminum Die-Cast Camlock Couplings:

- Sturdy and Long-Lasting Design: our zinc-aluminum die-casting process ensures that each coupling is characterized by high strength and durability, maintaining reliable performance even under high pressure and challenging conditions across various applications.

- Efficient Connection and Disconnection: the double-lock design facilitates tool-free, rapid connections and disconnections, enhancing operational efficiency in settings where frequent changes are necessary.

- Excellent Corrosion Resistance: zinc-aluminum alloys provide high resistance to corrosion, ensuring long-lasting functionality even in humid or chemically aggressive environments.

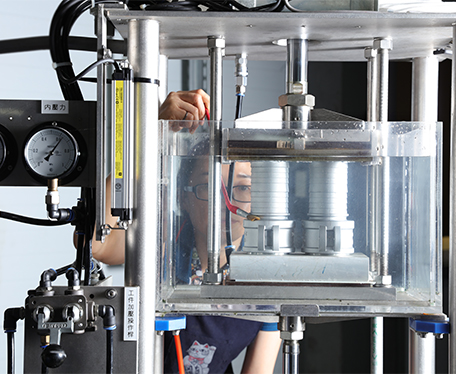

- Precision and Sealing Excellence: our die-casting technology offers precise dimensional accuracy, and every coupling undergoes thorough leak testing to ensure optimal sealing performance.

Applications of Aluminum Die-Cast Camlock Couplings:

- Liquid and Gas Transmission: ideal for quick connection and disconnection of water, oil, chemicals, and more, especially in industrial piping systems. These are suitable for gas transmission tasks involving natural gas and compressed air.

- Agriculture and Irrigation Systems: used in irrigation setups for hose connections, aiding in the transfer of liquid fertilizers and pesticides.

- Construction, Industrial, and Firefighting Systems: applied to connect water pipes and pump equipment on construction sites for flexible water supply. Couplings connect hoses to enhance emergency responsiveness in firefighting systems.

- Chemical, Manufacturing, and Environmental Management: utilized in chemical processing for secure chemical transfers to prevent leaks and contamination. Effective for rapid material changes during manufacturing processes and liquid transfer in wastewater treatment facilities.

- Food and Beverage Industry: facilitates safe and hygienic liquid transport in food processing and beverage production sectors, particularly in brewing and dairy.

Why Choose Chi Tai Zinc-Aluminum Die-Cast Camlock Couplings

- Expertise in Mold Design: with 40 years in mold development, Chi Tai minimizes porosity and shrinkage through advanced casting techniques, ensuring excellent product sealing.

- High Airtight Assurance: we employ vacuum die-casting technology in connection with vast mold runner design experience to reduce porosity and air pockets, ensuring superior air tightness in our products. Each product undergoes rigorous air pressure testing before leaving our facilities, ensuring consistent quality. Over the past decade, we have sustained a 0% air leakage rate across two million Camlock couplings delivered.

- Comprehensive Quality Inspection: every product undergoes stringent inspections to meet superior air-tightness standards. We offer custom design and assembly services to ensure the highest quality in Camlock couplings.

- Extensive Development Capabilities: we have successfully developed over 100 die-cast Camlock coupling molds within three years by applying our mold design expertise. These molds have been put into production to address the high-volume needs of our clients.

Chi Tai Casting has developed long-term partnerships with leading global companies, and is well-regarded in the industry. Our zinc-aluminum die-casting products are extensively utilized in various industries for their high performance and reliability. We are dedicated to providing high-quality Camlock couplings through advanced technology and a rigorous quality management system, ensuring each product's excellence under high pressure and demanding environments. Choose Chi Tai for optimal solutions to your Camlock coupling requirements.